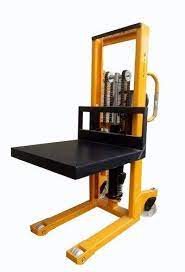

A hand-operated platform stacker is a manually powered lifting device designed to assist in material handling tasks, such as lifting and stacking pallets, crates, or other heavy loads in warehouses, factories, and retail spaces. Unlike electric stackers, which require a power source, hand-operated stackers are entirely manual, making them an economical, eco-friendly, and versatile option for various industries.

Key Features of Hand-Operated Platform Stackers

-

Manual Operation: Hand-operated stackers are powered by a hydraulic pump or mechanical system activated by hand, foot pedal, or lever. The operator controls the lifting and lowering of loads using these mechanisms, which makes them simple to use without the need for electricity or batteries.

-

Versatility: These stackers are designed to handle a wide range of material handling tasks, from lifting pallets to transporting boxes. The adjustable forks or platform can accommodate various sizes of loads, making them ideal for small to medium-sized operations.

-

Compact Design: Hand-operated stackers are typically lightweight and have a compact design, allowing them to maneuver easily in tight spaces like narrow aisles or crowded storage areas. This feature makes them highly suited for environments with limited floor space.

-

Durability: Built with high-quality materials such as steel, hand-operated platform stackers are designed to be durable and withstand heavy use in demanding work environments. The sturdy construction ensures a long service life and minimal maintenance costs.

-

Load Capacity: Hand-operated stackers can typically lift loads ranging from 200 to 2000 kg, depending on the model. This makes them suitable for handling heavy goods without the need for powered equipment, especially in situations where power sources are unavailable.

-

Safety Features: Most hand-operated stackers come with built-in safety features, such as overload protection, non-slip handles, and foot brakes to secure the stacker during operation. These features ensure safe handling of heavy loads and reduce the risk of accidents in the workplace.

-

Cost-Effective: Without the need for batteries or power cords, hand-operated stackers are a cost-effective solution for material handling. They require less maintenance compared to electric stackers and incur fewer operational costs, making them an attractive option for smaller businesses or those with budget constraints.

Applications of Hand-Operated Platform Stackers

-

Warehousing: These stackers are commonly used in warehouses to lift and transport pallets, crates, and boxes. Their compact size and manual operation allow for easy maneuvering in tight spaces, which is crucial for efficient warehousing operations.

-

Manufacturing: In manufacturing facilities, hand-operated stackers help move raw materials or finished products from one station to another, aiding in assembly lines, packing, or shipping tasks.

-

Retail: Retailers often use platform stackers to restock shelves, transport goods from storage to the shop floor, and organize backroom inventory. Their ability to lift moderate weights without electricity makes them ideal for small retail outlets.

-

Workshops: In auto-repair shops and other industrial settings, hand-operated stackers are used to lift heavy machinery parts, tools, and equipment, offering ergonomic support to workers handling heavy-duty tasks.

Advantages of Hand-Operated Stackers Over Powered Stackers

-

No Power Dependency: Hand-operated stackers are independent of any power source, making them suitable for outdoor or off-grid environments, reducing downtime caused by battery charging or electrical failure.

-

Lower Maintenance: Since these stackers do not rely on complex electrical systems, the maintenance required is minimal. Hydraulic components may occasionally need service, but overall, they are far less prone to malfunction than electric models.

-

Eco-Friendly: Without the need for power, these stackers do not emit any pollutants and have no energy consumption, contributing to an eco-friendly working environment.

-

User Control: Operators have greater control over the speed and height adjustments, reducing the likelihood of errors or accidents during operation.

Conclusion

Hand-operated platform stackers offer a practical, versatile, and economical solution for businesses that require efficient material handling. Their simplicity in design, durability, and ease of use make them a popular choice in industries such as warehousing, retail, manufacturing, and more. With no reliance on power sources, they are ideal for smaller operations or environments where electric stackers may not be feasible. Durable, reliable, and cost-effective, hand-operated stackers are an essential tool for any facility focused on optimizing its material handling processes.